Repmold changes how manufacturing works making it faster and less harmful to the environment. It moves you from a digital design file to a ready-to-use part almost . This method is shaking up how parts are made today. Tasks that used to take weeks in traditional manufacturing now take just a few days with remarkable precision.

Traditional manufacturing takes a serious toll on the environment. Factories release large amounts of greenhouse gasses, which play a role in climate change and pollution. At the same time, landfills fill up with waste that does not break down staying there for decades. Repmold gives people a strong alternative by prioritizing sustainability. It turns used items into new resources and helps close the loop in production.

This guide dives into what repmold is all about how it stands apart from traditional techniques, and why it holds more importance in 2025. It also looks into how this unique way of making molds ties to booming production efficiency, alongside the global move to embrace sustainability and digital shifts. If you’re someone who knows industry terms like repl mode or replmon commands, or you’re just starting to learn about this area, this article lays out the core idea of this game-changing method.

Understanding Repmold and Its Relevance in 2025

The word Repmold blends “rep” from replication or repetition with “mold,” meaning shape or structure. It introduces an idea that highlights both stability and creativity. Repmold refers to a specific mold-making and replication method built to create accurate copies of parts using reusable mold systems. This modern technique specializes in making identical pieces over and over while keeping quality and dimensions precise.

Explanation and background of the term

Molding has been around for thousands of years, with early societies using clay, stone, and metal molds to make tools and objects. The version of Repmold we recognize today took shape much later, as mass production became the norm during the industrial revolution. By the mid-20th century, industries needed faster ways to produce plastic parts for all sorts of uses. This demand pushed inventors to create mold systems that allowed flexibility and reuse setting the stage for the Repmold technology we rely on now.

What sets Repmold apart from older mold-making methods

Traditional molds take a lot of time to design and create. It can often take weeks or months to finish and perfect a single mold. Repmold however, simplifies this process. Manufacturers using it can complete their work faster while achieving better outcomes. Regular molds are built to last for a short period, but Repmold focuses on being stronger more flexible, and usable for a longer time.

Cost also puts Repmold ahead. It helps companies reduce waste and spend less time on labor without lowering quality. Its accuracy avoids frequent mistakes and improves how well each final product performs.

The growth of replication-based manufacturing

Repmold technologies use newer materials such as high-strength steel composite mold shells, and additive manufacturing methods. Combining old techniques with modern innovations helps Repmold meet the needs of industries today.

Industries like automotive, consumer goods, aerospace, and medical are turning to Repmold more and more. They are drawn to how Repmold makes accurate copies and . This allows companies to adapt faster to customer demands and market shifts while still keeping quality and precision intact.

As worries about the environment become more serious, Repmold’s skill in using materials and cutting down on waste during production makes it stand out as a green option compared to traditional methods. By reusing molds for different projects, businesses can lower how much harm they do to the environment.

The Repmold Process Explained

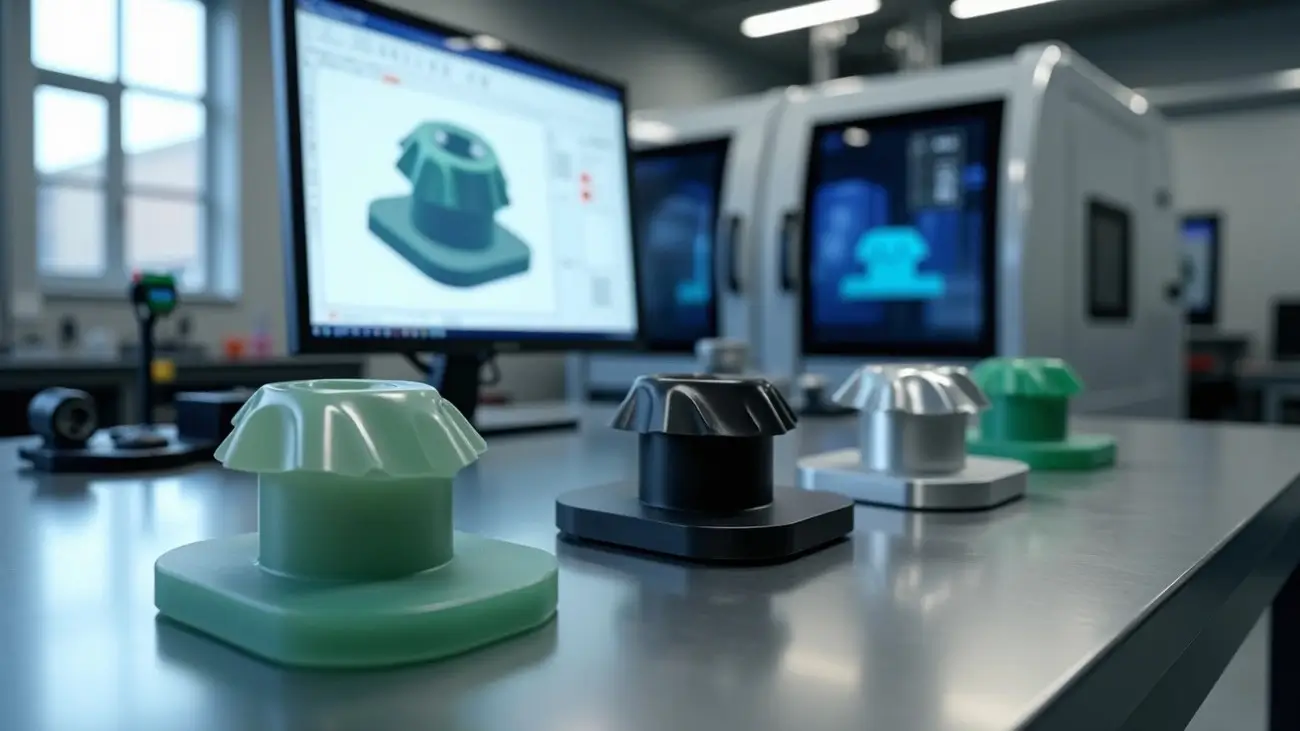

The Repmold system combines accurate digital designs with hands-on crafting to produce perfect replicas through an easy five-step process.

Step 1: Digital designing with CAD models

Everything starts online as engineers design detailed plans with advanced CAD tools. This important first step establishes accuracy even in tiny details serving as a virtual guide for the whole production process. The digital model allows designers to test how it might work in the real world before building anything helping to spot problems on.

Step 2: Making the master mold

Once the digital design is finished, the process shifts to creating a physical master mold from the virtual model. This step often uses CNC machining 3D printing, or a mix of both. To achieve fine details, some producers rely on 2-photon polymerization. This 3D printing method allows for resolutions as small as 100 nm and delivers surface roughness of just a few nanometers. The master mold becomes the base that all later copies depend on.

Step 3: Making replicas with different materials

When the master mold is ready, the next step kicks off with the replication process. Various materials like metals, plastics, composites, or advanced polymers are either poured injected, or pressed into the mold. This flexibility with materials makes the repmold technique useful in many different fields. What comes out is an exact copy that mirrors the original design with impressive precision.

Step 4: Testing and refinement

After that, all prototypes go through rigorous testing to check durability, function, and how precise their dimensions are. If any tweaks are needed, designers can update the digital model without starting everything over. This trial-and-error process helps improve designs faster compared to older methods that might force a full redo of the tooling.

Step 5: Scaling to produce at large volumes

When the prototype gets validated, the repmold system proves its worth by allowing efficient large-scale manufacturing. Its precise technology helps produce components with uniform quality even when making them in bulk. This method cuts down waiting times, reduces expenses, and boosts flexibility in manufacturing.

Practical Use and Industry Applications

Repmold technology now plays a role in various industries transforming how production gets done in many fields. Let’s take a look at how different industries use this advanced method.

Automotive: Engine parts and testing materials

Repmold helps car makers build precise engine parts and testing tools with great ease in the auto industry. They use this technology to make everything, including detailed dashboard designs and essential engine parts. Repmold’s ability to cut production expenses while keeping up high-quality standards plays a big part in helping the automotive world. In electric cars, it helps create unique parts used in batteries and energy systems.

Medical: Personalized implants and surgery tools

In healthcare, Repmold plays a crucial role in shaping medical devices where accuracy cannot be compromised. It helps produce custom implants, prosthetics, and surgical tools that adhere to strict regulations. Repmold also allows researchers to create prototypes of new medical ideas so they can test and improve designs faster. Its ability to tailor solutions stands out when crafting medical tools for individual patients.

Consumer goods: Limited-run electronics and devices

From smartphones to wearable gadgets, makers of consumer electronics rely on Repmold to make fitted parts. The industry trusts Repmold’s skill in handling quick design shifts, which is critical in a fast-changing market. Many consumer gadgets combine plastic and metal parts—materials that Repmold processes with expertise.

Aerospace: Precision parts with lightweight designs

The aerospace field needs accurate and tough components, which are areas where Repmold performs well. Their tech creates parts that are lightweight but strong enough to handle extreme conditions . These made pieces play a direct role in keeping aircraft both safe and efficient.

Construction: 3D printing and prefab buildings

Today, construction companies use Repmold-related tools like 3D printing to make prefabricated parts for buildings. This method can cut construction time by up to 70 percent and reduce labor needs by as much as 80 percent when compared to older techniques. Projects like modular homes and footbridges highlight how adaptable this technology can be. While construction is a newer field for this kind of innovation, these uses show it could shape the future in big ways.

Advantages and Obstacles of Repmold

Using Repmold brings clear benefits but also real challenges to today’s manufacturers. I’ve seen how it works across a variety of fields.

Lower costs and quicker prototyping

Repmold slashes production times shrinking cycles from months to just days. This shift gives companies a huge edge over competitors. It replaces tricky manual steps with automation, which lowers mistakes and trims waste. That cuts production costs too. To make fast prototypes without needing pricey tools smaller businesses can use this approach. It opens up quick testing even with tight budgets. The efficiency improvements make up for start-up costs fast. Big factories often save millions every year this way.

Eco-friendly and less material waste

Repmold offers clear eco-friendly advantages. It uses materials more and cuts down leftover scrap. This makes it a strong choice to support corporate green policies. Manufacturers can save even more by using recycled materials. That means they get sustainability and cost savings all in one.

Creative freedom and flexible designs

Repmold handles both simple and very intricate shapes with ease. This ability helps manufacturers adjust designs . It supports customization while keeping things efficient. Industries that change designs often benefit the most since they can respond faster to what the market wants.

Challenges: High upfront costs and scaling issues

Getting started with repmold costs a lot upfront. Companies need special tools, software, and training programs. Small businesses often adapt , but larger manufacturers may find it harder to expand these processes to whole production lines.

Need to train workers and maintain quality

Another challenge is the steep learning curve. Workers need proper training to get the most out of the system. Keeping quality high is key—monitoring equipment wear helps avoid flawed parts and ensures all products share the same features.

Wrap-up

Repmold brings together efficiency, sustainability, and precision in modern manufacturing like never before. This guide has shown how the technology blends old-school mold-making methods with digital advancements to build a strong manufacturing approach. The five-step process—from designing to producing at scale—gives manufacturers more control over their production while helping cut both waste and production time.

Repmold proves its flexibility when you look at how different industries use it. Car makers depend on it to craft engine parts, doctors turn to it to make personalized implants, tech companies enjoy its exactness for gadgets, aerospace teams love its balance of being sturdy and lightweight, and construction crews are now testing its use in making pre-made building pieces.

Repmold brings obvious benefits, but it comes with challenges that businesses need to think about . The upfront cost is often high, and companies must rely on trained workers to use the technology . Despite these hurdles, the rewards often make it worthwhile in the long run. It helps businesses save money, speed up prototyping, waste fewer materials, and have more freedom with designs, making it a smart option to consider for innovative manufacturers.

By 2025, Repmold will take on a bigger part in manufacturing strategies across the globe. This technology fits well with the rising need to achieve sustainability, improve customization, and boost production efficiency. Learning about this cutting-edge method isn’t just helpful—it’s a must for those in today’s manufacturing field. Whether you aim to use Repmold in your operations or just want to learn about fresh production approaches, this technology stands as a key step toward sustainable and efficient manufacturing.

FAQs

Q1. What is Repmold and how is it different from regular mold-making? Repmold is a modern method for creating molds and replicas that helps make the same parts over and over with precise quality and accurate dimensions. It stands apart from older mold-making techniques because it simplifies the whole process. This lets manufacturers complete it faster while focusing on strength, flexibility, and longer-lasting molds.

Q2. What are the main steps in the Repmold process? The Repmold method includes five key steps. First, designers start with digital design and CAD modeling. Next, they craft the master mold. Then, replication happens using different materials. After that, they test and refine the results. , adjustments are made to scale the process to produce more replicas. This process blends digital accuracy with hands-on skills to make high-quality replicas .

Q3. Which industries use Repmold technology? Different industries rely on Repmold technology. In the automotive world, it helps make engine parts and testing tools. Medical fields use it to create custom implants and surgical instruments. Consumer goods industries use it to produce small batches of electronics and gadgets. Aerospace experts use it to build lightweight and precise parts. Construction companies apply it to manufacture prefabricated or 3D-printed structures.

Repmold technology brings many advantages, like cutting costs speeding up prototyping, and lowering material waste. It supports eco-friendly practices and provides better options to customize and design products. Manufacturers can produce accurate copies fast, adapt to market shifts, and keep quality high while spending less on production.

Q5. What challenges are associated with implementing Repmold technology? Using Repmold technology has challenges like needing a lot of money at the start to get special machinery, programs, and training tools. Companies also need trained workers who know how to use it well and keep standards high. Expanding it can be tough too when big manufacturers want to use it across all their production lines.

1 thought on “What is Repmold? An Easy Guide to Today’s Mold Making”